This apparatus is applicable for the drying and auxiliary squeezing action of wet tubular textiles, chiefly cotton textiles.After two turns of inflation and squeezing, the cloth gets flat and wrinkle-free. It can act as a substitute for the conventional centrifugal dewatering apparatuses and wet spreading apparatuses.

Double padder balloon squeezing machine

Product Detail

Advantages of the Two-Padder Ballon Squeezing Machine

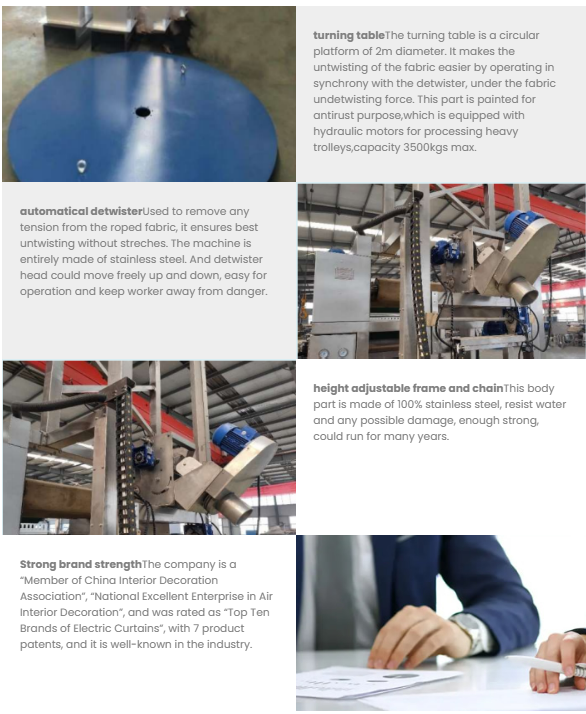

Made from 100% 304 stainless steel

Comes with a de-twister (E+L technology)

Rope-type fabric squeezing system

Two padders in a double trough design (with a temperature-controlled washing trough and chemical trough)

Automatic balloon inflation system

De-twister mechanism adjustable for height

Gomplast (SP) rubber-covered rollers

PLC control system

Software and equipment to the latest version

Fabric outlet: swing-type

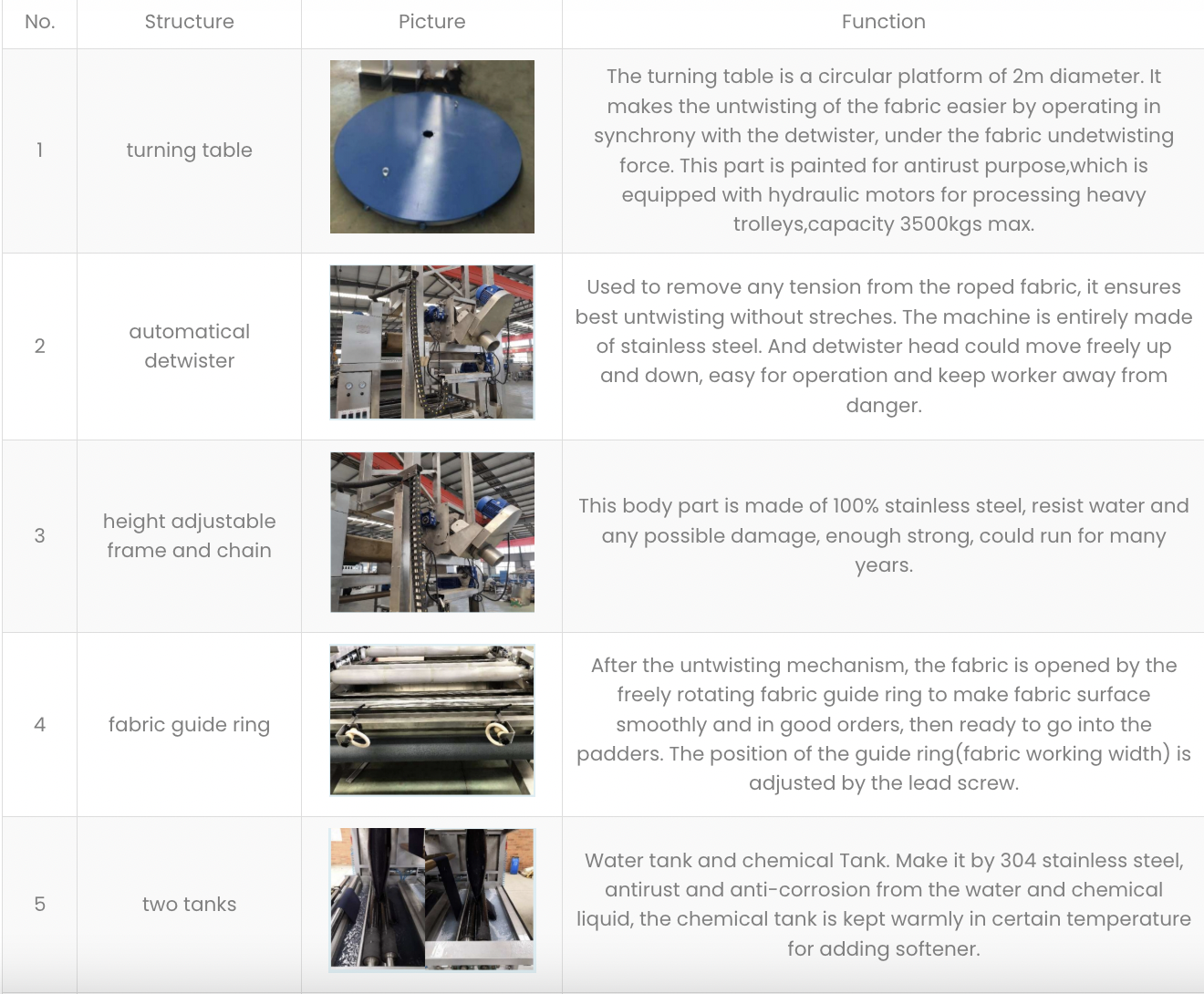

Functions and Features of the Double Padder Balloon Squeezing Machine for Tubular Fabric

It is meant to straighten out the twisted rope-like structure of tubular fabrics after they have been dyed or completed any other processing steps. Then, with the help of two dipping troughs and squeezing parts, it makes sure that the fabric comes out without any wrinkles.

This equipment has realized high automation, large output capacity, and user-friendly operation with efficiency; hence it is one of the preferred choices in China’s dyeing and finishing industry. The all-stainless-steel de-twisting and drying system has increasingly become an important popular part of the textile finishing process.

An attractive design, the unit’s structure and side sheets are of good quality carbon steel plates, subjected to acid pickling and phosphating treatment, and coated with fine paint. The pans and shields are made from top-notch stainless steel with excellent workmanship.

This machine will take over hydro-extractors, openers, and the softening agent treatment processes. It is particularly intended for the processing of rope-form tubular fabric subsequent to dyeing. Presently, opening the rope-form fabric and automatically extracting moisture can be accomplished quite easily, doing away with multiple machines and manual operations.

A line made for working with round cloth after it’s washed and colored, able to blow air into the cloth, put on softeners, and take off or reduce wetness or softening liquids. Quickness and force can be changed easily to suit making needs.

This machine gets rid of the creases and wrinkles on fabric that are usually left by old hydro-extractors. It solves this problem by joining two semi-continuous ways into one continuous operation, making both extraction and coating in just one step. This machine can do many tasks nonstop—opening, ballooning, extracting, stretching, and evenly compressing knitted fabrics—all in just one process.

Configuration

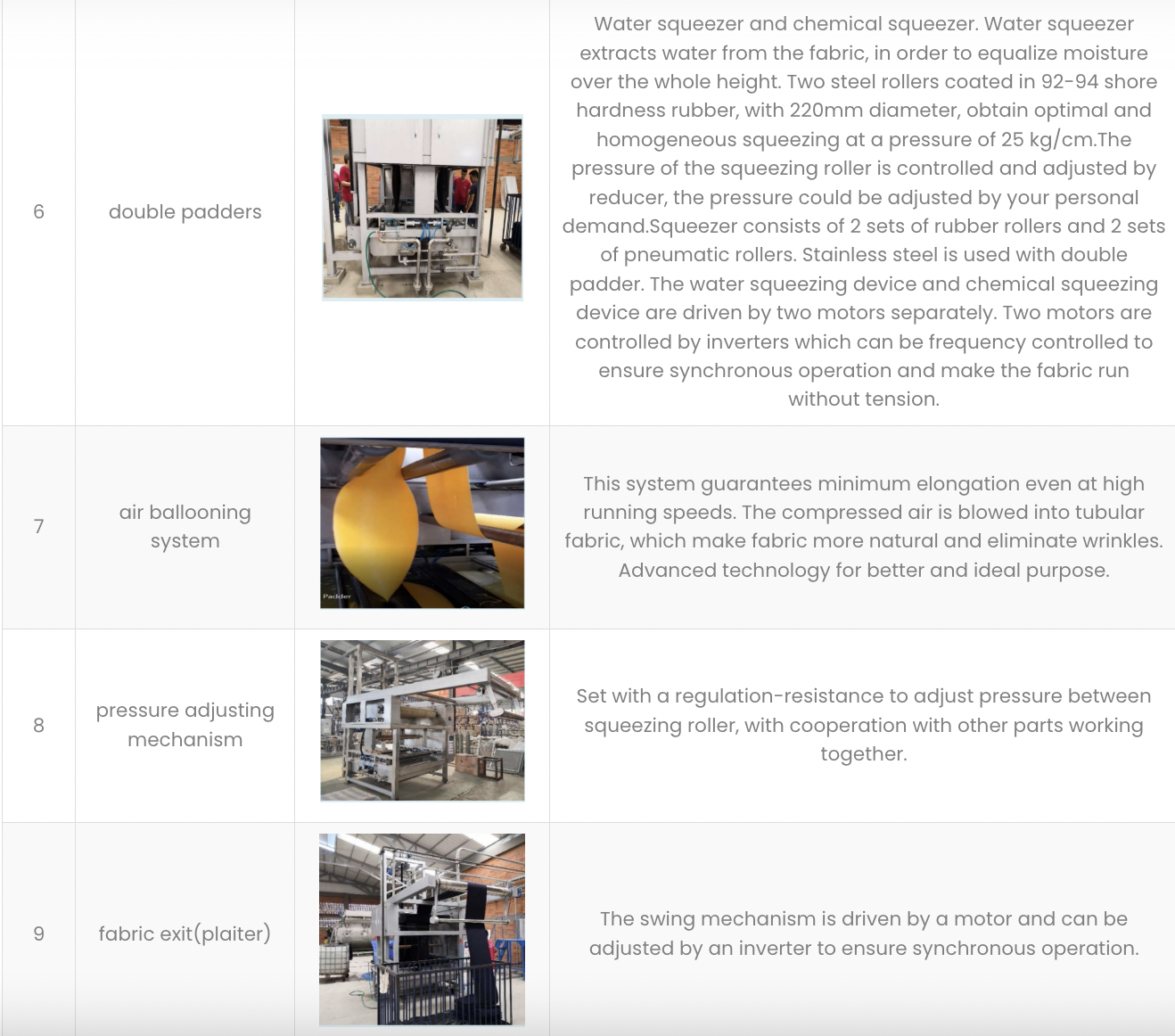

Parameter table

| Suitable for | wet tubular knitted fabrics after dyeing machine |

| Production capacity | 10-15ton/day |

| Working width | 1400mm |

| Working speed | 3-80m/min. |

| Installed power | 11.45kW |

| Compressed air | 0.35-0.6MPa |

| Steam consumption | 50-100kg/h |

Contact us now for a quote or more information