The Condensate Flake Maker uses chilled rollers and adjustable knives to efficiently convert heated liquids into solid flakes, providing improved product quality, consistency and ease of use with customizable flake specifications.

Drum Flaker

Product Detail

flaker, flake machine, drum flaker, chemical flaker.

Overview

As a professional supplier of drum flaker systems, we offer high-performance, durable, and industry-compliant solutions for the chemical, pharmaceutical, and cosmetic industries. This 2 ton/hour drum flaker integrates advanced flaking technology, precision manufacturing, and reliable components to deliver stable performance, uniform flakes, and extended service life.

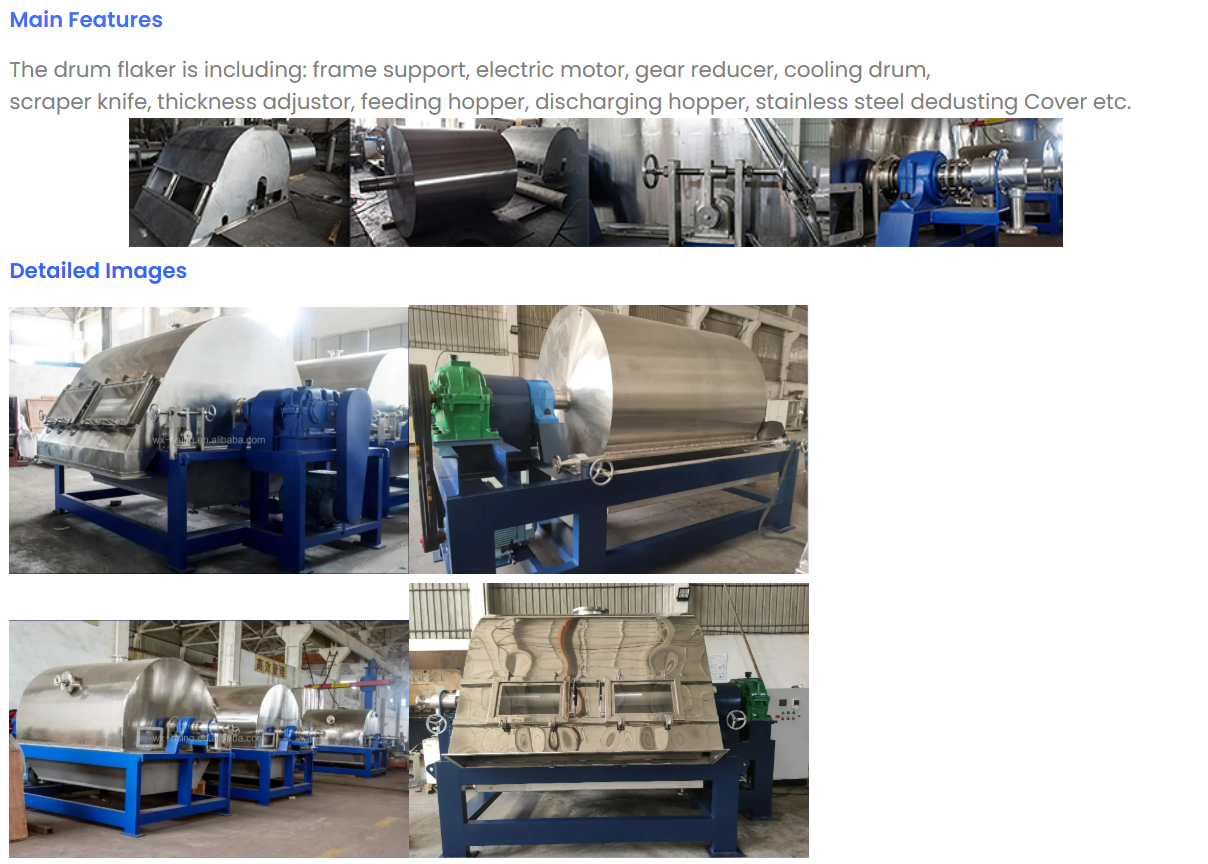

Machine Structure

The drum flaker mainly consists of:

Frame bracket

Motor and gearbox

Cooling drum

Adjustable scraper system (2 sets)

Thickness control unit

Feed hopper with heating coil

Discharge hopper

Stainless steel dust cover with observation windows

Material Specifications

Contact Parts: 304 stainless steel

Frame Bracket: Carbon steel with hot-dip galvanization

Drum and Trough: Fabricated according to standards for atmospheric steel containers:

JB/T4735.1-2009

JB/T4735.2-2009

JB/T47003.1-2009

Drum & Assembly Standards

Hydrostatic Test: Drum tested under 0.3 MPa water pressure

Radial Runout: ≤ 0.1 mm

Axial Movement: ± 0.2 mm

Surface Finish: Polished drum exterior

Scraper Contact: ≥ 80% contact length with drum surface, no abnormal noise during operation

Applied material for key parts and test standards

—— The parts of stearic acid in contact with soap material is 304 stainless steel,

Machine frame support made of carbon steel hot spray galvanized.

—— The drum and material trough of the flaker is manufactured and inspected as per the specification of Steel Vessel

in normal pressure, the machining, welding and assembling to be made according to the general condition of

JB/T4735.1-2009, JB/T 4735.2-2009,JB/T 47003.1-2009.

—— The drum will be done the water pressure test under 0.3MPA after finishing the manufacturing.

—— The data after assembling: radial runout of drum ≤0.1mm, axial transmission±0.2mm.

—— The contact between scraper and drum should be even, the contact line will be not less than 80% of the whole length. There should be no bumping and abnormal noise when running.

The outside shell of the drum should be treated by polishing.

Customer Service

Pre-Sales Service

Our expert consulting team offers full support for product selection, technical details, and application matching.

After-Sales Service

We provide a comprehensive service system with quick technical response via phone, email, or online platforms.

Packaging & Delivery

Packaging: Naked packing with key components protected in wooden crates

Delivery Time: Ships within 50 working days

Contact us now for a quote or more information